Processes

Highly specialized in turning, milling and assembly processes

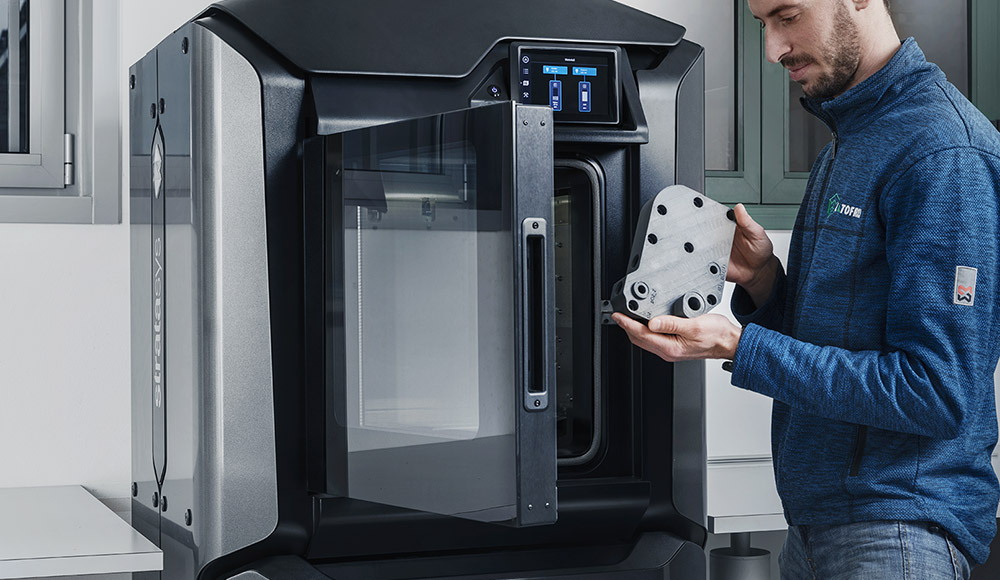

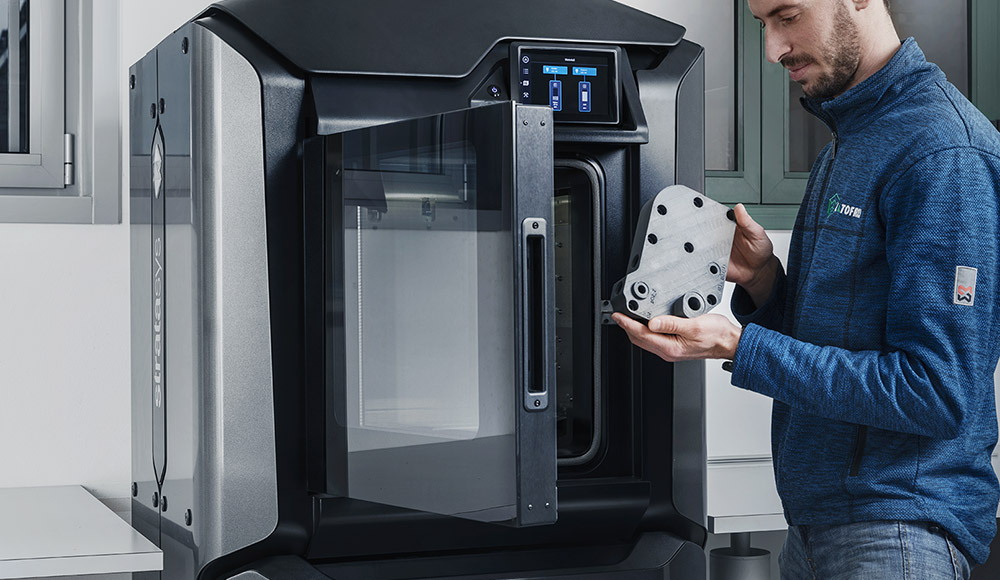

INVESTMENT IN TECHNOLOGY

Opting to invest continuously in rapidly advancing technologies means that we were able to specialize in turning and milling processes and assembly of extremely high precision mechanical components, offering those who trust in us solid guarantees of excellent results and production times.

INDUSTRY 4.0 MANAGEMENT

By adopting a full Industry 4.0 management and production model we can analyse and monitor every stage of the production process in real time. The interconnected ERP, MES and WMS software allows us to monitor the OEE (Overall Equipment Effectiveness) of each system for continuous improvement.

HIGHLY SKILLED AND CONTINUOUSLY TRAINED TEAM

We rely on highly skilled and experienced personnel, constantly updated through a comprehensive training programme, because we firmly believe that the most valuable asset of a future-facing company is its people.

Machine park

To meet the demand for high quality on time, we use the most advanced processing technologies, a critical factor in our large and continuously expanding machine park, with multiple turning and milling stations, machining centres and robotic islands for serial production of turned and milled components.Production

CNC MACHINES TURNING SECTION

2 horizontal machining centres

HELLER MC16.1

1 horizontal machining centre

HELLER MC16.2 with FASTEMS FPC multipallet system

3 horizontal machining centres

HELLER H1000

1 horizontal machining centre

HELLER H2000

1 horizontal machining centre

HELLER H2000 with FASTEMS FPC multipallet system

1 horizontal machining centre

HELLER H2000 with STS multipallet system

1 horizontal machining centre

Doosan NHP4000

1 horizontal machining centre

Doosan HC400

1 horizontal machining centre

Mazak VARIAXIS 630-5X (5-axis) with robot loader

2 vertical machining centres

Mazak VARIAXIS 630-54 (5 axis)

1 vertical machining centre

Brother TC31-A (4 axis)

1 vertical machining centre

Brother TC31-A (4-axis) with cobot

2 vertical machining centres

Brother TC31-A (4-axis) with robot loader

1 vertical machining centre

Brother TC32BN-QT (4-axis) with robot loader

1 vertical machining centre

Brother M140X2 (5-axis) with robot loader

1 vertical machining centre

Brother R450X2 (4-axis) with cobot

1 vertical machining centre

Brother R450X2 (4-axis) with robot loader

1 vertical machining centre

DOOSAN VC510

1 vertical machining centre

DAH LIH MCV1020

1 vertical machining centre

FAMUP

1 vertical machining centre

MITSUBISHI OMNIS1270

1 vertical machining centre

SHE HONG PRO-800A

Machinable sizes (in mm):

Horizontal CNC: up to 630x630x630

Vertical CNC: up to 1020x600x600

CNC MACHINES MILLING SECTION

1 twin spindle turning centre

MURATEC MD 120

3 twin spindle turning centres

MURATEC MD 200

1 twin spindle turning centre

MURATEC MT 12

2 twin spindle turning centres

MURATEC MT 20

2 twin spindle turning centres

MURATEC MW 200

1 twin spindle turning centre

MURATEC MT 200

1 vertical turning centre

EMAG VSC250

1 vertical turning centre

EMAG VL5i

2 vertical turning centres

EMAG VSC7

2 vertical turning centres

DOOSAN V400M

2 turning centres

MORI-SEIKI DURATURN 2550 with robot loader

1 turning centre

OKUMA LB 15 I with robot loader

1 turning centre

OKUMA LB 300 MY

1 turning centre

OKUMA LB 300

1 turning centre

Mazak QT QUICK 6T

1 turning centre

STAR SR20 RII

1 turning centre

SCHAUBLIN T130

Machinable sizes (in mm):

Horizontal CNC: up to 280x1000 in diameter

Vertical CNC: up to 500x500 in diameter

Swiss-type lathe CNC: up to 23x205 in diameter

MEASURING

MEASURING SYSTEMS

1 DEA GLOBAL 3D gauge mm 100x700x700

1 DEA MISTRAL 3D gauge mm 100x700x700

1 OGP Smartscope 250 optical gauge

1 Taylor Hobson profile projector

2 Talysurf surface profilometer

1 Talyround 265 dimensional measuring bench

2 hardness testers (Galileo 7 Afri)

1 optical microscope

1 Karl Deutsch ultrasonic thickness gauge

Calibration machines, micrometers, bore gauges and other bench testing equipment

PRODUCTION DEPARTMENT MEASURING SYSTEMS

3 ZEISS Duramax DT250 3D measuring machines mm 500x500x500

1 ABERLINK Xtreme measuring machine mm 300x300x200

1 ABERLINK Xtreme measuring machine mm 400x400x300

1 ViciVision M618 optical measuring machine mm 600x180

Other processes

METAL WASHING SYSTEM

IFP KP 600 MAX