Quality

To further raise our standards, in 1996 we acquired UNI EN ISO 9002:1994 system certification, updated constantly to the current UNI EN ISO 9001:2015.

In 2010 we obtained ISO/TS 16949 for the automotive sector, updated to the current IATF 16949:2016 certification.

In 2020 we obtained UNI EN ISO 14001:2015 certification for our environmental management system.

In 2010 we obtained ISO/TS 16949 for the automotive sector, updated to the current IATF 16949:2016 certification.

In 2020 we obtained UNI EN ISO 14001:2015 certification for our environmental management system.

Materials, processes and products checked scrupulously

1

Materials testing

The materials we use are subjected to non-destructive tests, chemical and mechanical analysis carried out by accredited laboratories.

2

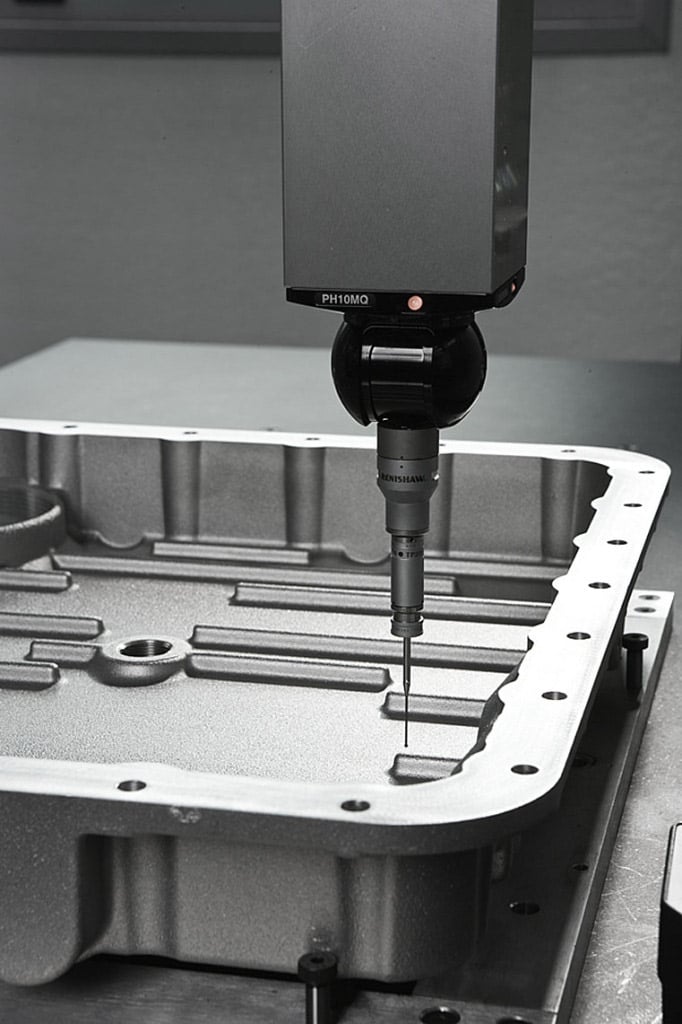

Onboard machine control

Onboard control takes place with the workpiece on the machine, with bench testing, calibration and 3D measuring instruments.

3

SPC station

We use SPC (Statistical Process Control) stations to constantly monitor processing phases.

4

End of process control

In addition to the process controls, products are subjected to strict control to certify full conformity before delivery to the customer.