Precision mechanics driven by experience and innovation

Consulting, design and complementary machining processes offer customers the benefit of relying on one single partner.

Processes

Highly specialized in turning, milling and assembly processes

Opting to invest continuously in rapidly advancing technologies means that we were able to specialize in turning and milling.

Discover our machine park

We combine high production capacity and absolute quality thanks to a very large and technologically advanced machine park.

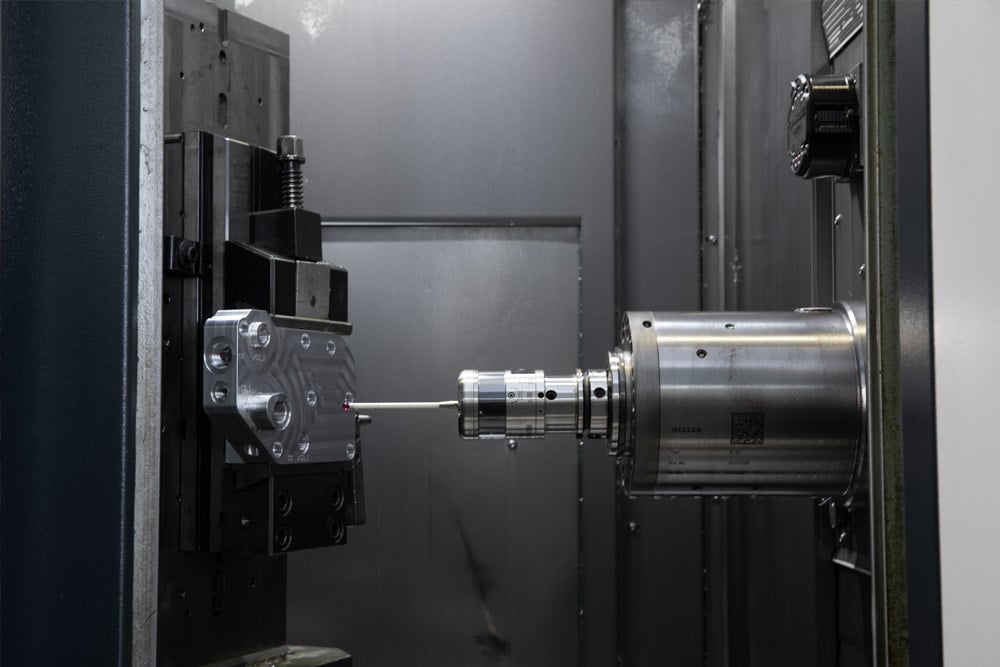

Turning

Machinable sizes (in mm)

- Horizontal CNC: up to 280×1000 in diameter

- Vertical CNC: up to 500×500 in diameter

- Swiss-type lathe CNC: up to 23×205 in diameter

Find out more

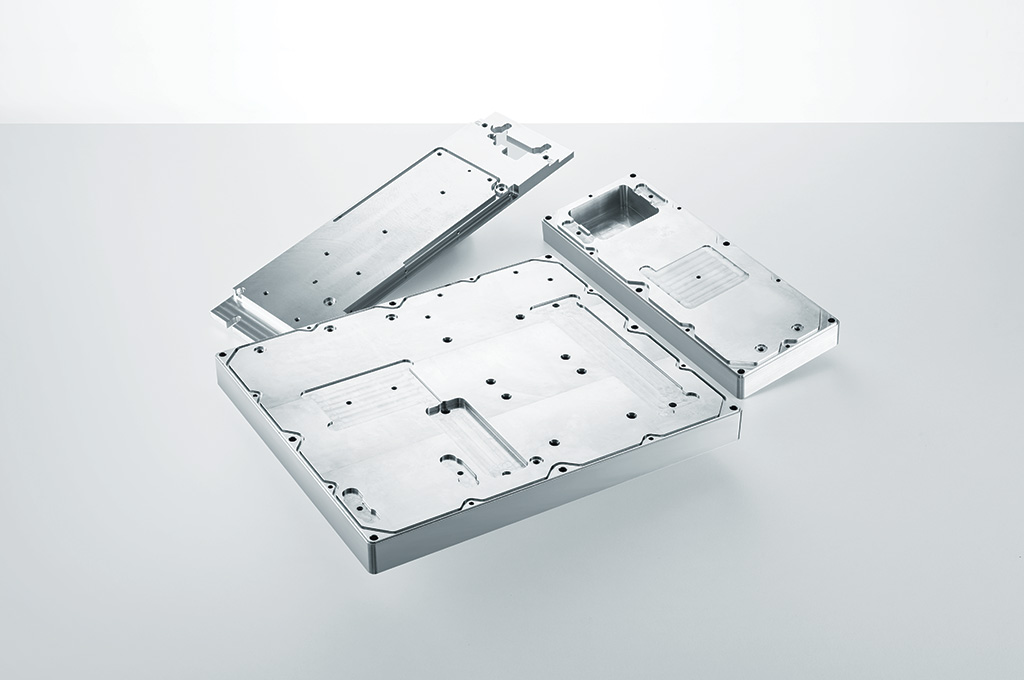

Milling

Machinable sizes (in mm):

- Horizontal CNC: up to 630x630x630

- Vertical CNC: up to 1020x600x600

Find out more

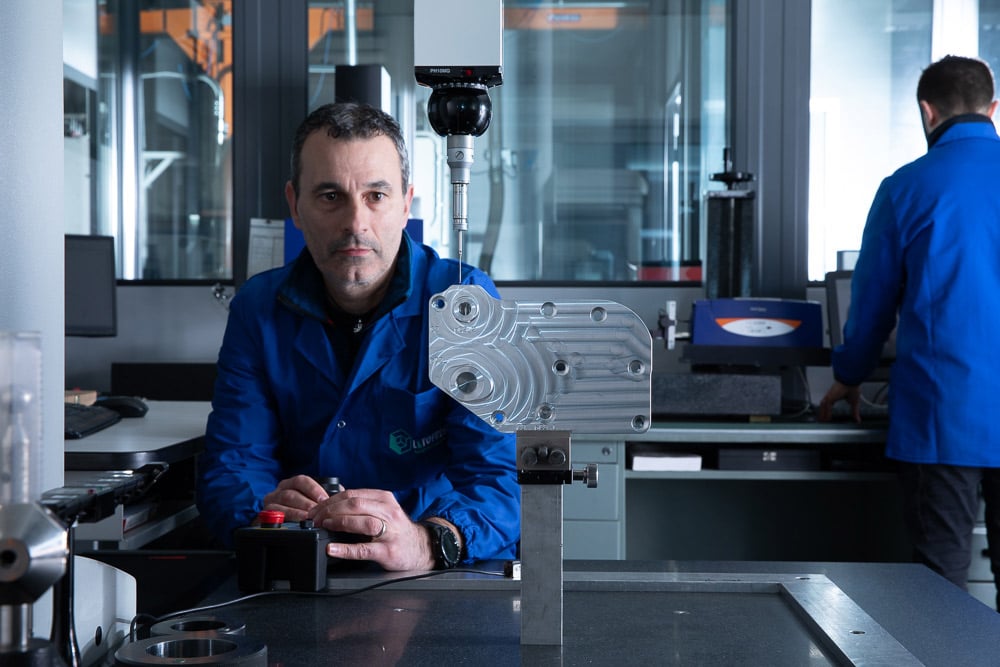

Measuring systems

Find out more

Production department measuring systems

Find out more

Metal washing system

Find out more

Sectors

Our sectors of specialization

Automotive

Production of components for the automotive and transport industry: flanges, covers, pins, axles, bushings, plates, and iron and aluminium casting.

Find out more

General mechanics

Production of mechanical components and assemblies for the following industries: earth-moving equipment, agricultural machinery, industrial transport.

Find out more

Electromechanics

Production of components for the electromechanical industry: casings, flanges, covers, caps, axles.

Find out more

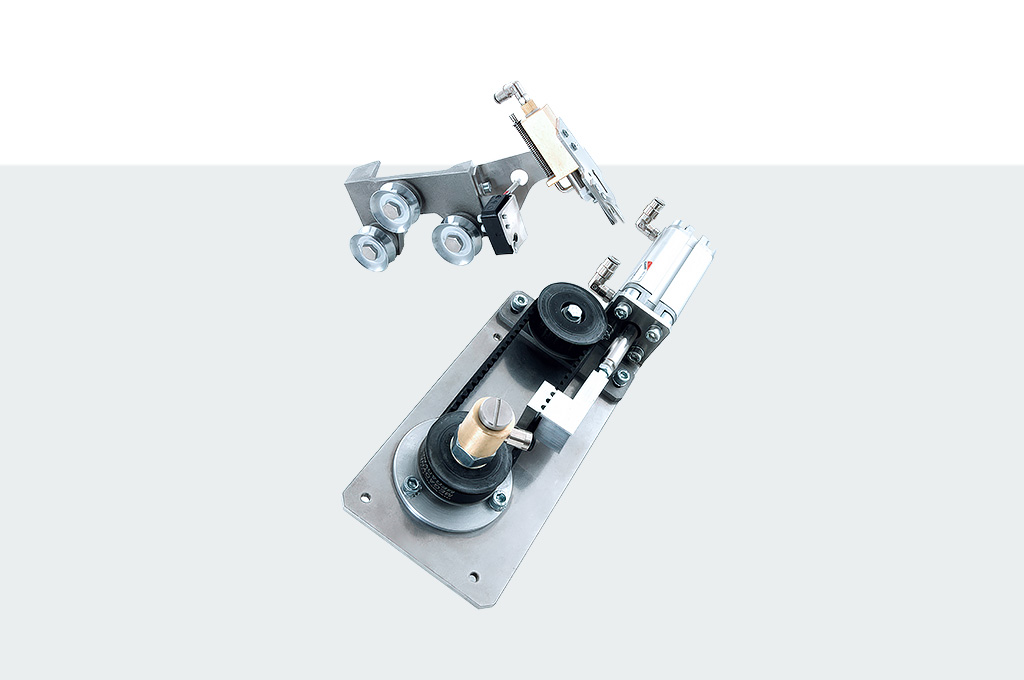

Textile machinery

Production of components and mechanical assemblies for textile machinery.

Find out more

Hydraulics and pneumatics sectors

Production of parts for the hydraulics and pneumatics sectors. Aluminium and stainless steel fittings, pistons, rods and housings.

Find out more

Sport

Production of precision components for the sports industry.

Find out more

Electronics

Production of components and mechanical assemblies for electronics and sensors.

Find out more

Railway

Production of railway components. spacers, rings, discs, cups, bushings, pipes, plates, covers, pins.

Find out more

Services

One contact for the entire production cycle

Support in product development providing expertise through consulting and design, and complementary processes for the main machining job.

Advanced Product Quality Planning

Design and production

Materials selection

Heat treatments

Finishing treatments

Washing

Marking

Assembly

Quality

System certifications and strict checks

Our culture of quality underpins every aspect of our business through continuous investment in the improvement of production and organizational processes.

Sustainability

Comprehensive commitment for a better present and future

Operating sustainably is a key part of our philosophy.